Ziel

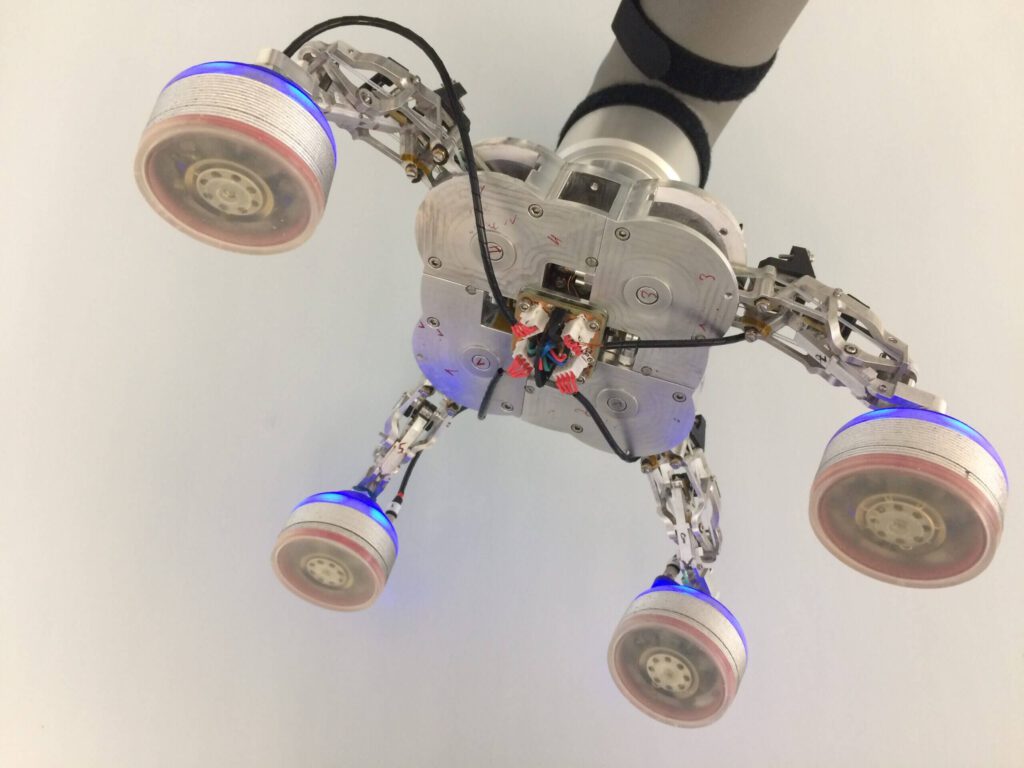

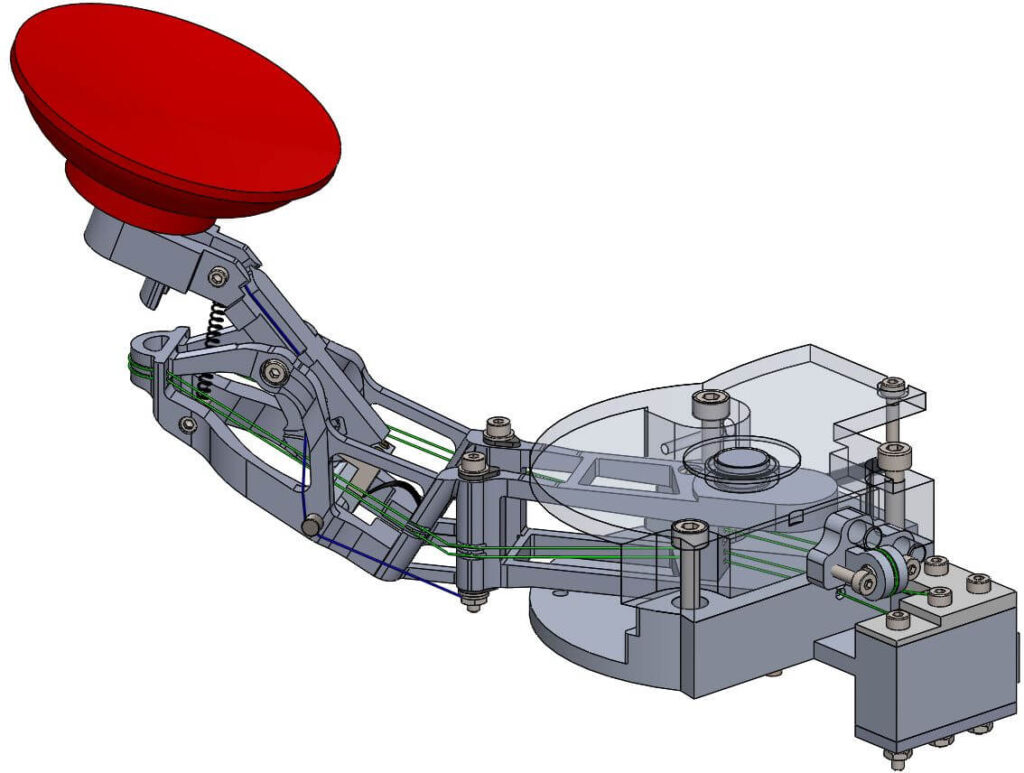

Ein automatisch, rekonfigurierbarer Endeffektor, der sich mit Hilfe von Formgedächtnisantrieben (FGLs) in mehreren Dimensionen an eine spezielle Geometrie anpassen kann.

Ergebnis

- Endeffektor als Komplettsystem mit FGL Antrieb

- Integriertes Bremssystem auf FGL Basis

- Energiefreies Halten eines Werkstücks

- Möglichkeit der Montage von bistabilen FGL Saugern

- Hohe Anpassungsfähigkeit durch zwei Freiheitsgrade im System

Ausblick

In Montagelinien, in denen sich ändernde Werkstückgeometrien zu erwarten sind, könnte das smarte, auf FGL basierte Greifersystem seinen Einsatz finden. Durch die hohe Anpassbarkeit und die leichtgewichtige Bauweise kann das FGL basierte Komplettsystem mit jeglichem in der Industrie verwendeten Roboter betrieben werden. Zudem ist auch dieses FGL System hinsichtlich Haltekraft skalierbar was den Anwendungsbereich in der Industrie enorm vergrößert. Die integrierte FGL basierte Bremse macht die Anwendung zusätzlich energieeffizient und ermöglicht ein energiefreies Halten des Werkstückes.

Anwendungsbereiche

Überall, wo größere – auch komplex geformte – Werkstücke gegriffen und bewegt werden müssen.

- Automobilindustrie,

- Glasindustrie,

- Metallindustrie,

- usw.

Entwickelt von

Dr. Paul Motzki, Yannik Goergen, Lukas Zimmer